How To Do Activity Based Budgeting

It was during my early days as a financial analyst. The company I worked for was struggling with managing its resources effectively. That’s when I stumbled upon Activity-Based Budgeting.

It was like finding a compass in the middle of a dense financial forest. Implementing ABB not only helped the company regain control over its finances, but it also gave me a fresh perspective on budget management.

Understanding Activity-Based Budgeting is crucial for managing your business finances effectively. It’s more than just crunching numbers; it’s about understanding the pulse of your business operations. By aligning your budget with your activities, you can make informed decisions, optimize your resources, and steer your business towards growth and profitability.

Key Takeaways

Imagine you’re planning a party. You wouldn’t just say, “I’m going to spend $200,” without knowing what you need, right? You’d probably make a list: $50 for food, $30 for decorations, $20 for drinks, and so on. That’s essentially what an Activity-Based Budget is.

It’s a budget that breaks down your expenses based on different activities in your business. Instead of just saying, “We’ll spend $10,000 next month,” you’d say, “We’ll spend $3,000 on manufacturing, $2,000 on marketing, $1,000 on delivery, and so on.” This way, you have a clear idea of where your money is going and can make more informed financial decisions.

Understanding the Basics of Activity-Based Budgeting

Have you ever tried to bake a cake without knowing how much flour, sugar, or eggs you need? You might end up with a culinary disaster on your hands. Similarly, running a business without understanding where and how your resources are being used is like trying to bake that cake blindfolded. And that’s where Activity-Based Budgeting (ABB) comes into play.

In simple terms, ABB is your recipe for financial success. It tells you exactly how much of each resource you need (and where you need it) based on the activities or tasks being performed in your business. It’s like having a financial blueprint that guides you in allocating resources more accurately and efficiently.

Now, I know what you’re thinking: “Finance and fun don’t usually go together.” But who says we can’t have a little chuckle while we’re navigating the labyrinth of budgeting? Here’s a joke to lighten the mood: Why don’t accountants trust calculators? Because they can always count on their fingers!

Now, let’s talk about a traditional budgeting versus ABB. Imagine you’re planning a road trip. With traditional budgeting, you would set aside a lump sum of money for the whole journey without considering the specifics. It’s like saying, “I have $500 for this trip,” without thinking about the cost of gas, food, accommodation, and those irresistible roadside souvenirs.

On the other hand, ABB is like meticulously planning your budget for each segment of your trip. You allocate funds for gas based on the distance you’ll cover, for food based on the number of meals you’ll have, and so on. That way, you know exactly where your money is going, and you can make adjustments as needed.

So, in essence, while traditional budgeting gives you a bird’s eye view of your finances, ABB lets you zoom in and manage each activity’s budget effectively. It provides a clearer picture of where your resources are going, helping you make more informed decisions and ensuring smooth business operations.

Activity-Based Budgeting Versus Zero Based Budgeting

Activity-Based Budgeting is a method of budgeting that focuses on activities or tasks rather than departments or units. It identifies the key activities in business processes and allocates costs to these activities based on the resources required to perform them. This approach allows for a more accurate and detailed budgeting process, as it takes into account the specific needs of each activity.

On the other hand, Zero Based Budgeting is a budgeting method that requires you to start from scratch every year. It involves justifying and building your budget from zero based on the current needs and priorities of your business. This approach helps to eliminate unnecessary costs and encourages thorough analysis of each expense. However, it can be a time-consuming and resource-intensive process.

So, which one is better for your business? It ultimately depends on your priorities and the level of detail you need in your budgeting process. If you want a more accurate and detailed budget that considers the specific needs of each activity, ABB may be a better fit for your business. However, if you want to thoroughly evaluate and justify each expense in your budget, ZBB may be a more suitable method.

Activity-Based Budgeting Versus Activity-Based Costing

Activity-Based Costing and Activity-Based Budgeting are like two sides of the same financial coin. ABC is a method for determining the cost of each activity involved in producing a product or service. It’s about looking back and understanding where your money went.

On the other hand, the Activity-Based Budgeting method is for planning future costs based on those activities. It’s about looking forward and deciding where your money should go. So while ABC helps you understand your past and present financial situation, ABB helps you plan for your financial future.

Step-by-Step Guide to Implementing Activity-Based Budgeting

Alright, now that we’ve set the stage, let’s dive into the nitty-gritty of implementing the Activity-Based Budgeting method in your business. It might seem like a daunting task, but remember, every expert was once a beginner. So let’s break it down together, shall we?

Make sure to download our free Excel template to follow along:

Step 1: Identify Your Activities

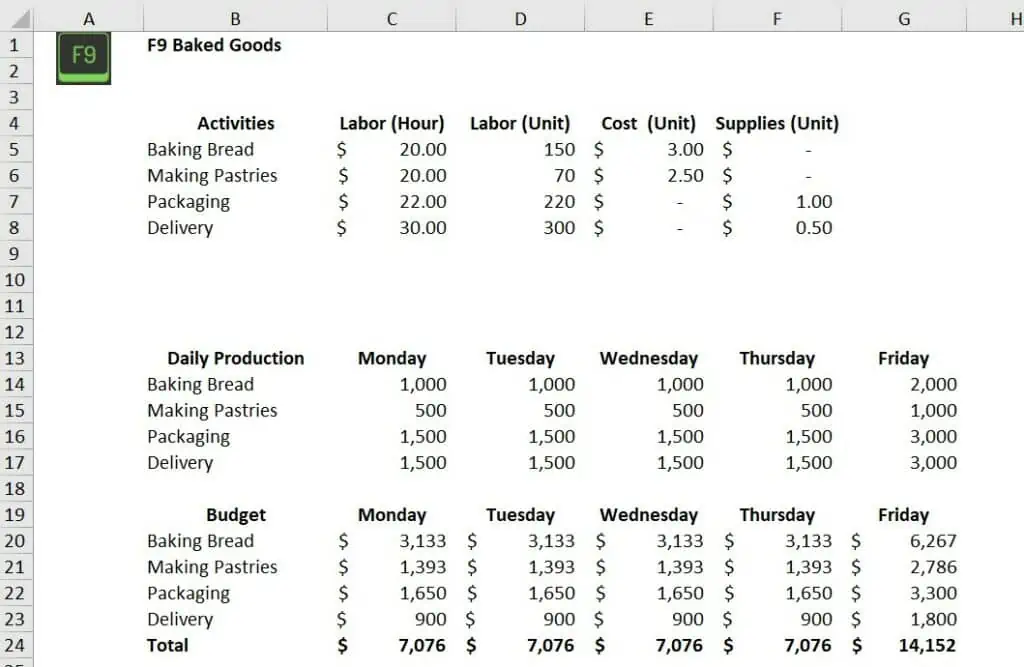

The first step is to identify all the activities or tasks that your business performs. Think of it as taking inventory of everything you do. For instance, if you run a bakery, your activities might include baking bread, making pastries, packaging, and delivery.

Step 2: Assign Costs to Each Activity

Once you have your list of activities, it’s time to assign costs to each one. This is where ABB really shines. Instead of just looking at your total expenses, you’re breaking them down based on each activity. Remember our road trip analogy? It’s like calculating the cost of gas for each leg of the journey.

Step 3: Identifying Cost Drivers

Next, you need to determine the cost drivers, i.e., what causes the costs for each activity. In our bakery example, the drivers could be the number of loaves baked, the hours spent on baking, or the number of deliveries made. Identifying these drivers will help you understand what influences your costs and where you can make adjustments.

Step 4: Create Your Budget

Now comes the fun part – creating your budget! Based on the costs and drivers you’ve identified, you can allocate resources for each activity. It’s like planning your road trip budget based on the distance, meals, and accommodations.

Step 5: Monitor and Adjust

Finally, keep an eye on your budget and adjust as needed. Just like you might need to reroute during your road trip due to unexpected detours, you’ll need to fine-tune your budget as your business evolves.

Now, I won’t sugarcoat it – the activity-based budget process can come with its challenges compared to a traditional budget. It requires a detailed understanding of your operations and when you incur costs. It can also be time-consuming. But remember, Rome wasn’t built in a day. Start small, perhaps with one department or project. As you get the hang of it, you can gradually implement ABB across your entire business.

Activity-Based Budgeting Advantages

Alright folks, it’s time for the grand reveal: the benefits of mastering Activity-Based Budgeting! If you’ve been following along, you’re already getting a sense of what this powerful tool can do. But let’s really dig into the gains that ABB can bring to your business.

Improved Accuracy

With ABB, you’re not just making educated guesses about where your resources are going. It’s like having a GPS for your finances; you know exactly where you’re headed and how to get there. This leads to more accurate budgeting, which in turn helps you avoid nasty financial surprises down the line.

Greater Efficiency

Activity-Based Budgeting is all about ensuring that every dollar works as hard as it can for your business. By aligning your budget with your activities, you can identify areas where you might be overspending and find cost savings. It’s like realizing you’ve been using premium gas for a car that runs perfectly fine on regular. Who doesn’t love finding ways to save?

Informed Decision-Making

One of the biggest advantages of ABB is the clarity it provides. When you understand the cost driver of each activity, you can make more informed decisions about where to invest your resources. It’s like knowing exactly how much bang you’re getting for your buck.

Now, let’s talk about some real-life success stories. Take the case of ABC Bakery (name changed for privacy). They were struggling with high production costs and low profitability. After implementing an Activity-Based Budget, they discovered that their packaging costs were through the roof due to custom boxes for each product. By switching to standardized packaging, they were able to drastically reduce costs and boost profitability.

Then there’s XYZ Manufacturing (name changed for privacy). They used ABB to identify that their assembly process was consuming a large portion of their budget. By streamlining the process and training their employees to work more efficiently, they were able to cut costs significantly.

Potential Pitfalls and How to Avoid Them

Let’s talk about some common pitfalls businesses encounter when implementing ABB and, more importantly, how to steer clear of them.

Overcomplicating the Process

Remember when you first learned to ride a bike? You didn’t start by tackling the Tour de France route. Similarly, when implementing ABB, it’s easy to get overwhelmed if you try to do too much too soon. Start small, perhaps with one department or project, and as you gain confidence, gradually expand your ABB implementation.

Neglecting to Involve the Team

ABB is not a one-person show. It’s like a choir performance; everyone needs to be in sync for it to work. Make sure to involve all relevant team members in the process. Their insights can be invaluable in identifying activities and cost drivers, and their buy-in will be crucial for successful implementation.

Ignoring the Need for Regular Updates

Implementing ABB isn’t a “set it and forget it” kind of deal. It’s more like tending a garden; it needs regular attention and care. As your business evolves, so will your activities and costs. Regularly review and update your ABB to ensure it remains accurate and relevant.

Have any questions? Are there other topics you would like us to cover? Leave a comment below and let us know! Make sure to subscribe to our Newsletter to receive exclusive financial news right to your inbox.